- This topic is empty.

-

AuthorPosts

-

22/12/2025 at 15:35 #5869

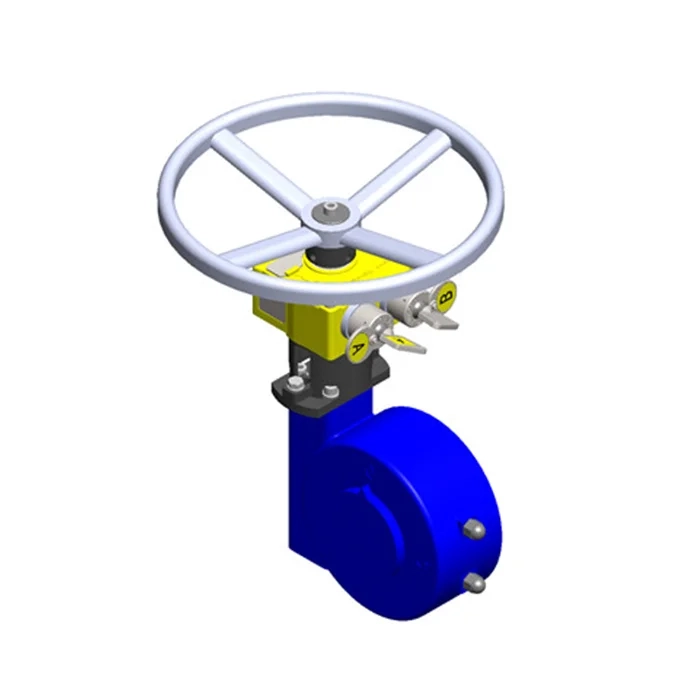

Mechanical valve interlock devices are vital for ensuring safety and operational efficiency in industrial systems. They are designed to enforce proper valve sequencing, preventing accidents, equipment damage, and costly downtime. However, improper installation of these devices can compromise their effectiveness, leading to safety hazards and operational inefficiencies. In this article, we explore the common mistakes to avoid when installing mechanical valve interlock devices and provide best practices to ensure safe and reliable operation.

Understanding Mechanical Valve Interlock Devices

Mechanical valve interlock devices are physical systems that prevent improper operation of valves. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment. Unlike electronic interlocks, mechanical interlocks rely on keys, cams, levers, or locking pins to enforce operational sequences, making them highly reliable in environments where electronic systems may fail.

The main purpose of a mechanical valve interlock is to:

-

Ensure that valves are operated in the correct sequence.

-

Prevent simultaneous operation of conflicting valves.

-

Reduce human error during maintenance, startup, or shutdown procedures.

-

Enhance overall safety and compliance with industry standards.

Despite their simplicity, mechanical interlocks require precise installation to function correctly. Mistakes during installation can render the system ineffective, posing serious risks.

Common Mistakes to Avoid

1. Ignoring Manufacturer Instructions

One of the most frequent mistakes is neglecting the manufacturer’s installation guidelines. Each mechanical valve interlock device is engineered for specific valve types, sizes, and operational sequences. Ignoring these instructions can lead to:

-

Improper fit or alignment.

-

Reduced mechanical strength or durability.

-

Increased risk of malfunction during operation.

Best Practice: Always read and follow the manufacturer’s installation manual carefully. Confirm that the device model matches the valve specifications and intended operational sequence.

2. Misalignment of Components

Mechanical valve interlocks rely on precise alignment of keys, cams, levers, or locking pins. Misalignment during installation can prevent the device from functioning properly. Common alignment errors include:

-

Mounting the interlock too loosely or too tightly.

-

Incorrect positioning relative to the valve stem.

-

Failing to ensure smooth movement of keys or locking pins.

Best Practice: Use proper measuring tools to ensure alignment. Test the device in its fully open and closed positions before finalizing installation.

3. Selecting the Wrong Interlock Type

There are various types of mechanical valve interlocks—key interlocks, cam-operated interlocks, ball and chain interlocks, and lockout/tagout devices. Installing the wrong type for a particular application can compromise safety. For example:

-

Using a simple key interlock in a complex multi-valve system may not enforce the correct sequence.

-

Using a cam-operated device on a valve not designed for cam attachment can damage both the valve and the interlock.

Best Practice: Evaluate the system’s complexity, valve type, and operational requirements before selecting the interlock type. Consult with the manufacturer for guidance if necessary.

4. Overlooking Environmental Conditions

Industrial environments can be harsh, with high temperatures, humidity, vibration, and exposure to chemicals. Installing a mechanical valve interlock without considering these factors can lead to premature wear, corrosion, or failure. Common oversights include:

-

Using standard steel interlocks in corrosive chemical environments.

-

Ignoring temperature limits for key materials.

-

Installing devices in areas prone to excessive vibration without proper support.

Best Practice: Choose materials and finishes suitable for the environment, such as stainless steel for corrosive conditions or reinforced components for high-vibration areas.

5. Improper Testing After Installation

Failing to test a mechanical valve interlock after installation is a critical mistake. Without testing, hidden issues such as misalignment, binding, or faulty sequencing may go unnoticed until an emergency occurs.

Best Practice: Conduct thorough testing of all operational sequences immediately after installation. Simulate real-world scenarios to ensure that the interlock functions correctly under normal operating conditions.

6. Neglecting Maintenance Access

Installing a mechanical valve interlock without considering access for maintenance can lead to difficulties in inspection, lubrication, or adjustment. Restricted access can result in:

-

Missed inspections.

-

Increased downtime during repairs.

-

Potential damage to the device during forced access attempts.

Best Practice: Ensure sufficient clearance around the interlock for routine maintenance. Follow manufacturer recommendations for lubrication points and inspection intervals.

7. Using Excessive Force

Mechanical valve interlocks are precision devices. Applying excessive force during installation can deform components, damage keys or cams, and compromise the locking mechanism. Common errors include:

-

Forcing keys into slots without proper alignment.

-

Over-tightening mounting bolts or screws.

-

Using improper tools for installation.

Best Practice: Install components gently, ensuring smooth operation without forcing parts. Use calibrated torque tools if specified by the manufacturer.

8. Ignoring Operator Training

Even perfectly installed mechanical valve interlocks can fail to prevent accidents if operators are not trained. Lack of training can lead to:

-

Improper key handling.

-

Bypassing the interlock sequence.

-

Attempting unauthorized modifications.

Best Practice: Provide comprehensive training to all personnel involved in valve operation. Include demonstrations, practical exercises, and clear documentation of operational sequences.

9. Failing to Label Interlocks Clearly

In complex systems with multiple valves, unclear labeling can confuse operators and lead to sequence errors. Common issues include:

-

Missing or illegible tags.

-

Incorrect labeling of valves or keys.

-

No visual guidance for emergency procedures.

Best Practice: Use durable, clear labels for all valves and interlocks. Include sequence numbers, operation directions, and safety warnings as part of the labeling system.

10. Not Planning for System Expansion

Industrial systems often evolve, with new valves added or operational sequences modified. Installing interlocks without considering future changes can complicate expansion and compromise safety.

Best Practice: Plan for scalability by choosing interlock systems that allow modular additions or easy reconfiguration of sequences.

Best Practices for Installing Mechanical Valve Interlock Devices

To avoid these common mistakes and ensure the safe and effective operation of mechanical valve interlocks, consider the following best practices:

-

Pre-Installation Assessment: Evaluate valve types, sequences, environmental conditions, and safety requirements.

-

Manufacturer Consultation: Seek guidance on device selection, compatibility, and installation procedures.

-

Precision Installation: Ensure proper alignment, torque specifications, and secure mounting.

-

Comprehensive Testing: Test each valve and interlock sequence under realistic operational conditions.

-

Operator Training: Educate personnel on proper use, emergency procedures, and maintenance protocols.

-

Regular Maintenance: Conduct periodic inspections, lubrication, and functional testing to maintain reliability.

-

Clear Documentation: Maintain records of installation, testing, and maintenance for regulatory compliance and future reference.

Conclusion

Mechanical valve interlock devices are essential for industrial safety, providing a fail-safe method to control valve operations and prevent accidents. However, improper installation can undermine their effectiveness, creating safety risks and operational inefficiencies. By understanding the common mistakes—such as ignoring manufacturer instructions, misalignment, selecting the wrong interlock type, and neglecting testing and training—industrial operators can avoid pitfalls and ensure the reliability of their interlock systems.

Following best practices for selection, installation, testing, and maintenance not only enhances safety but also improves operational efficiency and compliance with industry regulations. Investing the time and effort into proper installation of mechanical valve interlock devices is a small price to pay for the protection of personnel, equipment, and the environment

http://www.nudango.com

nudango -

-

AuthorPosts

- You must be logged in to reply to this topic.